|

|

|

|

|

|

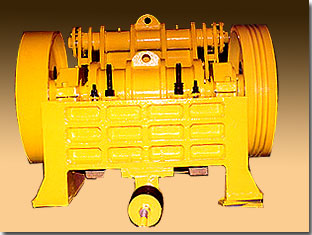

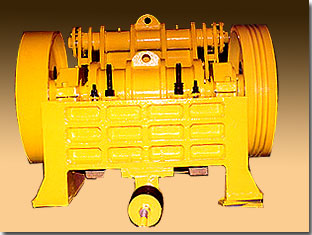

| Jaw crusher:- |

The working principal of Jaw Crusher is based on modern

design "CRUCHING WITHOUT RUBBING" The machine consists, two Jaws,

one fixed and the other moving . The opening between them is smaller

at the bottom and wider at the top. The pitman moving on an

eccentric shaft on bearing, swing lever (Moving Jaw) swing on center

pin. he Rock held in between two Jaws and crushed by mechanical

pressure.

|

|

|

Crusher Frame :- Crusher Frame is made of high

welding. As a welding structure, it has been designed with every

care so as to ensure that it is capable of resistant to bending

stress even when crushing materials of extremely hard.

Jaw stock :- Jaw Stock is also completely welded and

has renewable bushes, Particular importance has been given to jaw

Stock of a design resistant to bending stresses. All jaw stocks are

provided with a renewable steel Alloy or manganese steel toggle

grooves.

Pitman is made of high quality steel plates and

carefully stress relived after welding. The Pitman is fitted with

two renewable steel Alloy or manganese steel toggle grooves housings

for the bearings are accurately bored and faced to gauge.

Eccentric Shaft is machined out 'of Alloy Steel Fitted

with anti-friction bearings and is housed in pitman and dust proof

housing.

Anti-Friction Bearings are heavy duty double row

self-aligned roller-bearings mounted in the frame and pitman are

properly protected against the ingress of dust and any foreign

matter by carefully machined labyrinth seals.Crushing Jaws are castings of austenitic manganese steel

conforming to IS 276 grade I & II. The real faces of the

crushing jaws are levelled by surface grinding in order to ensure

that they fit snugly on the crusher frame and jaw stock. The

crushing jaws are reversible to ensure uniform wear and tear of

grooves.

|

|

The Wedge Setting is accessible and permits easy and reliable

setting of the width of the gap. The wedge block is fitted with a

renewable Alloy steel or manganese steel Toggle bearings.

Toggle Plates are of special quality hard iron with chilled

ends.

Side Plates are of special quality manganese steel

castings.

Lubrication of bearings is by grease gun through suitable

nipples.

Fly Wheels are made of good quality cast iron. Robust design,

machined and balanced, suitable for either flat or vee belt

drive.

| Jaw Crusher Size in Inch |

Recommended Feed Size in

Inch |

CAPACITY IN TONS/PER

HOUR WITH JAW SETTING AT MM/INCHES |

R.P.M. |

B.H.P. |

Approximate Weight in Kgs |

| 20/3/4" |

25/1" |

38/1/1.5" |

50/2" |

65/2.5" |

75/3" |

100/4" |

125/5" |

150/6" |

| 8 x

4 |

3.25 |

1 |

1.5 |

2 |

|

|

|

|

|

|

325 |

5.0 |

900 |

| 12 x

7 |

6 |

|

6 |

8 |

12 |

|

|

|

|

|

325 |

12.5 |

1800 |

| 16 x

9 |

8 |

|

|

12/15 |

15/18 |

18/20 |

|

|

|

|

325 |

20.0 |

3500 |

| 20 x

10 |

9 |

|

|

15/18 |

22/24 |

28/30 |

|

|

|

|

325 |

25.0 |

6000 |

| 24 x

12 |

11 |

|

|

|

28/30 |

32/34 |

38/40 |

|

|

|

325 |

40.0 |

7800 |

| 30 x

15 |

14 |

|

|

|

|

40/42 |

50/52 |

65/67 |

|

|

325 |

50.0 |

12000 |

| 32 x

20 |

18 |

|

|

|

|

|

|

70/72 |

80/82 |

|

275 |

75.0 |

15000 |

| 36 x

18 |

16 |

|

|

|

|

|

60/62 |

75/77 |

95/97 |

|

325 |

60.0 |

15000 |

| 36 x

24 |

22 |

|

|

|

|

|

|

75/77 |

95/97 |

110/112 |

275 |

100.0 |

22000 |

| 16 x

5 |

4 |

7 |

9 |

14 |

|

|

|

|

|

|

350 |

15.0 |

3000 |

| 20 x

5 |

4 |

8 |

12 |

18 |

|

|

|

|

|

|

350 |

20.0 |

4200 |

| 24 x

6 |

5 |

14 |

10 |

12/20 |

26/28 |

|

|

|

|

|

350 |

30.0 |

6500 |

| 36 x

6 |

5 |

14 |

20 |

15/28 |

40 |

|

|

|

|

|

350 |

40.0 |

8500 |

| 42 x

8 |

7 |

16 |

22 |

30 |

45 |

|

|

|

|

|

325 |

50.0 |

11500 |

|

|